which of the following is a type of machine safeguarding punching

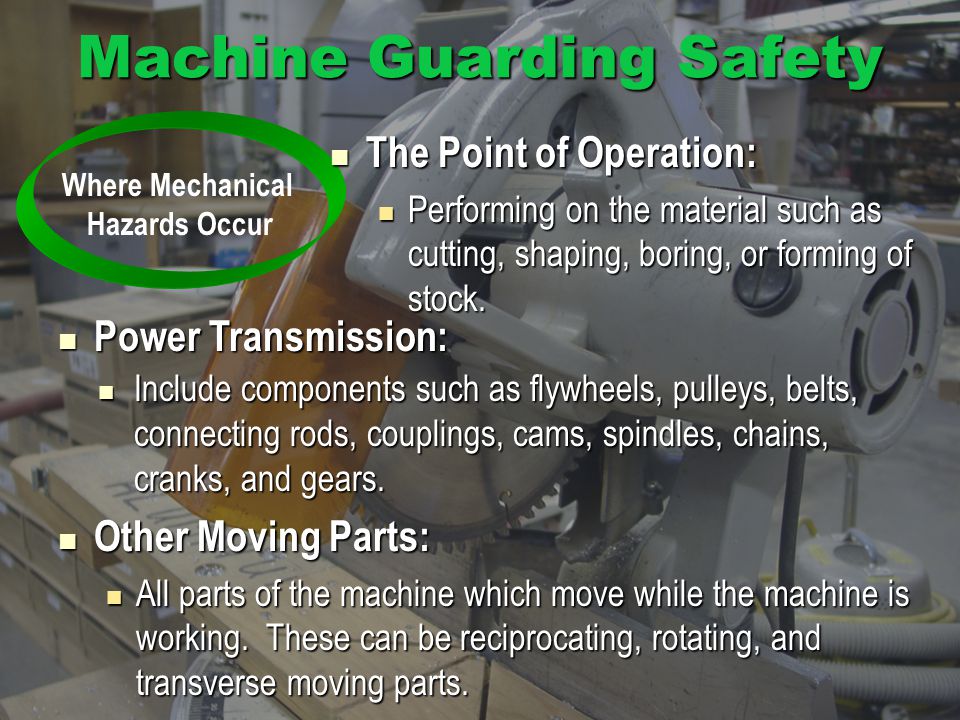

Power-transmission apparatuses flywheels pulleys belts chains couplings spindles cams and gears in addition to connecting rods and other machine components that transmit. These can include the movement of rotating members reciprocating arms moving belts meshing gears cutting teeth.

Machine guards can protect from the following hazards.

. The danger of this type of action occurs at the point of operation where stock is inserted held and withdrawn by hand. Which of the following is a type of machine safeguarding. Cutting Action 7 Figure 5.

This problem has been solved. Pull outs Restraints. The employer shall provide and ensure the use of properly applied and adjusted point of operation devices or guards for every operation performed on a.

Transversing Motion 7 Figure 4. Which of the following is a type of machine safeguarding. 4206 SAFEGUARDING THE POINT OF OPERATION.

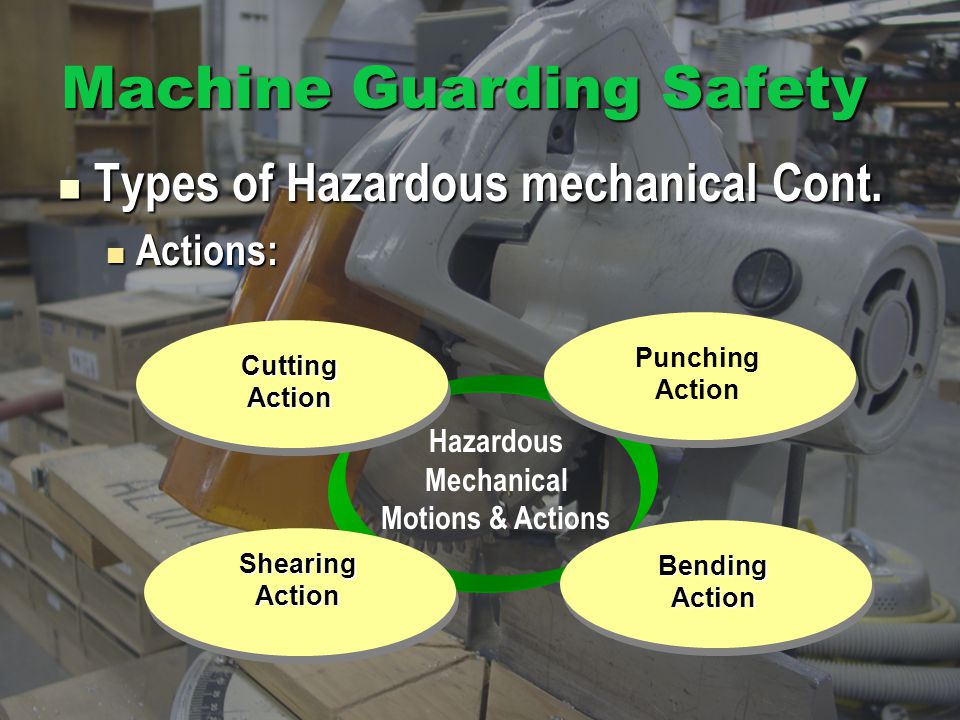

Punching action power applied to a slide ram for purpose of blanking drawing or stamping. - 18265042 Suppose you are 46 and have a 250000 face amount 14-year limited-payment participating policy dividends will be used to build up the cash value. The following are all machine safeguarding requirements except.

Primary Safeguarding Methods Two primary methods are used to safeguard machines. Machine safeguarding helps protect workers from preventable injuries in all three areas. There seem to be as many hazards created by moving machine parts as there are types of machines.

Which of the following is a type of machine safeguarding. The most common types of machine guards are. Machine guards are important because they protect operators and other individuals in the work area from hazards associated during the machines normal operation.

There seem to be as many hazards created by moving machine parts as there are types of machines. Rotating Motion 7 Figure 2. Types of Safeguarding Devices 13 List of Figures Figure 1.

Must prevent workers from lubricating a machine without removing the safeguard. Identify types of machine guards including types of devices used to safeguard machines. Two Hand controls Two hand Trip.

Commonly Used Machine Guards 12 Table 2. Which of the following is an exception to the general rule for safeguarding to prevent hazards during servicing and maintenance of machines. The following are some examples of machines requiring point of operation guarding.

Interlock guards make certain that the machine cannot be started until the guard screen is in the closed position and conversely the guard cannot be removed until the working parts have been stopped. Nip guard to in-running rolls and fixed railing or fencing to engines motors planning or shaping machine are of this type. Hazardous Mechanical Motions and Actions.

Which of the following is an exception to the general rule for safeguarding to prevent hazards during servicing and maintenance of machines. Must prevent workers from lubricating a machine without removing the safeguard. In-Running Nip Points 8 Figure 9.

EOSMS 308 Machine Guarding Program Page 4 1 Hazardous Parts of a Machine a Point of operation The point of operation is the point where material is positioned inserted or manipulated or where work such as shearing punching shaping. Machine Guarding OSHA 10-Hour Outreach Training General Industry. Which of the following is a type of machine safeguard.

The following are all machine safeguarding requirements except. Servicing or maintenance is not hazardous for employees b Maintenance is minimal and performed as an important part of production c Employer uses other safeguards which provide effective protection as required. Point of operation the area of a machine where it performs work on material.

Any part of a machine which ___ while in operation can cause a hazard. The Occupational Safety and Health Administrations OSHAs requirements for machine guarding are found in 29 Code of Federal Regulations CFR 1910 Subpart O Machinery and Machine Guarding as detailed below. Reciprocating Motion 7 Figure 3.

Good machine safeguarding makes it very difficult for anyone to be exposed to the danger zone. Punching Action 8 Figure 6. Crushed hands and arms severed fingers blindness -- the list of possible machinery-related injuries is as long as it is horrifying.

Bending Action 8 Figure 8. Chapter 1 - Basics of Machine Safeguarding Basics of Machine Safeguarding Crushed hands and arms severed fingers blindness -- the list of possible machinery-related injuries is as long as it is horrifying. OSHA Quiz 8 Machine Guarding.

What are the hazards associated with machine operation. Machines can cause a variety of injuries ranging from minor abrasions burns or cuts to severe injuries such as fractures lacerations crushing injuries or even amputation. Feeding and ejection methods.

Shearing Action 8 Figure 7. Which is the following is not a requirement for safeguards. Which types of moving parts need guarding.

Punching action results when power is applied to a slide ram for the purpose of blanking drawing or stamping metal or other materials. Area on a machine where the work is performed. Simply so what are the most common types of machine guarding.

A wide variety of mechanical motions and actions may present hazards to the operator. Typical machines used for punching operations are power presses and ironworker machines. The 5 most common ways of machine guarding.

Which of the following is a type of machine safeguarding. The following types of mechanical components present amputation hazards. Each piece of machinery has its own unique mechanical and non-mechanical hazards.

Machine guards are your first line of defense against injuries. Also what are the 2 types of primary safeguarding methods. O Punching O Feeding and ejection methods O Point of operation O In-going nip points Question.

Operating Machinery Safely With Machine Guarding Quad Plus

Machine Guarding Safety Cfr Ppt Download

Chapter 1 Basics Of Machine Safeguarding

Machine Guarding Safety Cfr Ppt Download

Chapter 1 Basics Of Machine Safeguarding

Chapter 1 Basics Of Machine Safeguarding

Chapter 1 Basics Of Machine Safeguarding

Chapter 1 Basics Of Machine Safeguarding

Machine Guarding Safety Cfr Ppt Download

Machine Guarding Safety Cfr Ppt Download